Beyond the Visible Spectrum

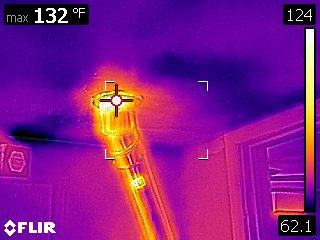

Traditional visual inspections have limitations - they rely on visible light and cannot penetrate surfaces to reveal hidden issues. Thermal imaging cameras measure infrared radiation (heat) emitted by objects and translate it into visual thermograms.

This unique capability allows inspectors to identify problems hidden beneath paint, drywall, or other building materials that would be impossible to detect with standard visual observation.

Key Advantage

Wet materials, electrical hot spots, and missing insulation have different thermal properties that thermal cameras can detect instantly.